ZOC Stud Weld is a leading manufacturer of weld studs, shear studs, and stud welding machines. We provide high-quality stud welding solutions for global industries.

ZOC Stud Weld is a trusted manufacturer of stud welding products in China since 1993. We specialize in weld studs, shear studs, ceramic ferrules, and stud welding machines—designed for heavy-duty industrial use and OEM customization. Contact us for high-quality supply and competitive factory prices.

Please feel free to contact us at any time for a quotation or further details.

Weld studs are specially designed metal fasteners that are permanently attached to a metal base through the stud welding process. Unlike traditional bolting or riveting, weld studs create a high-strength, one-sided fastening solution without the need for back-side access. They are widely used in construction, shipbuilding, automotive, steel fabrication, and industrial equipment manufacturing. Common types include shear studs, threaded studs, and deformed bar anchors. Weld studs ensure structural integrity, reduce labor time, and improve production efficiency. At ZOC Stud Weld, we manufacture a full range of weld studs with consistent quality and offer OEM customization to meet your exact project needs.

Weld studs attach in seconds with automated equipment, reducing labor costs and speeding up assembly time.

Compatible with various metals and thicknesses, making them ideal for diverse manufacturing applications.

Creates permanent metal-to-metal connection that's stronger than the base material, ensuring reliable performance.

Provides smooth surface appearance on opposite side with no visible fasteners, enhancing product aesthetics.

Eliminates need for drilling, tapping, and additional fasteners, saving both material costs and production time.

Allows for quick component attachment and removal while maintaining the integrity of the primary structure.

Weld studs work by creating a strong, permanent bond between a metal stud and a base metal surface using arc welding. In the process, an electric arc melts the end of the stud and the base material simultaneously. The stud is then pressed into the molten pool, forming a high-strength weld in just milliseconds. This one-sided fastening method requires no drilling, tapping, or backside access, making it ideal for structural applications in construction, shipbuilding, and industrial manufacturing. Stud welding ensures fast installation, excellent load capacity, and reliable long-term performance.

Weld studs are used to create strong, permanent fastenings in a wide range of industrial and structural applications. They are essential in steel construction, bridge building, shipbuilding, and power plants for securing steel plates, beams, and structural components. In automotive and manufacturing industries, weld studs are used to attach brackets, panels, and insulation mounts with precision and speed. Shear connectors (shear studs) play a key role in composite construction, improving load transfer between steel and concrete. With fast installation and superior strength, weld studs are ideal for any project requiring reliable, long-lasting connections.

High-quality carbon steel or stainless steel rods are sourced and inspected for chemical composition.

Rods are cut to exact lengths based on the required stud type and specification.

Using cold forming machines, the rod is shaped into studs under high pressure, ensuring uniform grain structure and mechanical strength.

External threads are rolled onto the shank using precision thread rolling machines for high dimensional accuracy.

Arc-ready tips are formed for better weld arc ignition, especially in shear studs or CD studs.

Surface finishes like zinc plating or passivation are applied for corrosion resistance.

Finished studs are sorted, labeled, and securely packed for shipment.

Weld studs are manufactured through a precise and standardized process to ensure strength, consistency, and weldability. At ZOC Stud Weld, we follow a complete in-house production flow, from raw material to final packaging.

Each batch is measured for length, diameter, thread pitch, and tip angle.

Studs are checked for defects, burrs, or deformation.

Rockwell or Brinell hardness tests ensure strength consistency.

Weld samples are tested to confirm arc stability and bonding quality.

Random samples are pulled to verify tensile strength.

Applied on surface-treated products to evaluate corrosion resistance.

We are committed to customer satisfaction by delivering high-quality stud welding solutions. At ZOC Stud Weld, we ensure every weld stud, ceramic ferrule, and stud welding machine meets your industrial needs with precision and reliability.

We are a trusted manufacturer committed to delivering high-performance stud welding products tailored to your industrial needs.

With over 30 years of manufacturing experience, ZOC Stud Weld understands the requirements of global factories, wholesalers, and OEM clients. Our team ensures reliable supply, stable quality, and professional service in every shipment.

Need assurance? We welcome all your questions and are ready to support your projects with confidence.

●Each step is rigorously inspected from materials to delivery, ensuring quality.

● We supply only premium weld studs, ceramic ferrules, and stud welding machines.

● Our products are manufactured using fully automated production lines for consistency.

● We support OEM & customized packaging based on your brand requirements.

● Competitive prices without compromising on quality.

● Fast response, on-time delivery, and flexible support for long-term cooperation.

Want to explore how we can work together? Let’s connect today.

At ZOC Stud Weld, we understand that customers are concerned about the safe transportation of welding studs, ceramic ferrules, and other accessories during international shipping. That’s why we prioritize secure packaging and logistics solutions to protect your products throughout the supply chain. Our reinforced packaging is designed to prevent damage during transit, ensuring that your order arrives in perfect condition—ready for immediate use. Partner with us for a hassle-free and reliable shipping experience.

Our Standard Packaging Methods:

Lightweight and cost-effective for general packaging.

Ideal for bulk loading and forklift handling.

Strong and secure for heavy or high-value goods.

Durable and protective for long-distance shipping.

Our Standard Shipping Methods:

Efficient for large cargo at a lower shipping cost.

Fast delivery for urgent and time-sensitive orders.

Stable delivery across long inland distances.

Flexible for short routes and door-to-door service.

Explore common questions about weld studs, materials, applications, and our OEM services. Whether you’re new to stud welding or looking for a reliable supplier, these answers will help guide your purchasing decisions with confidence.

A weld stud is a fastener that is welded onto another metal surface using arc or capacitor discharge welding, creating a strong permanent bond without holes or threads.

We supply weld studs in carbon steel, stainless steel, and aluminum. Material certificates can be provided for all batches.

Yes. We support customized lengths, diameters, and head types. OEM branding, packaging, and marking are also available.

With 5 production lines, we ensure fast delivery and stable supply for both bulk orders and customized production.

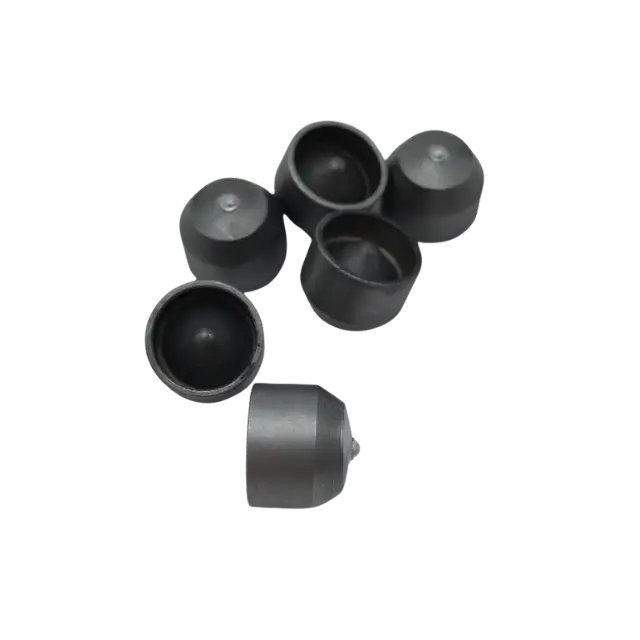

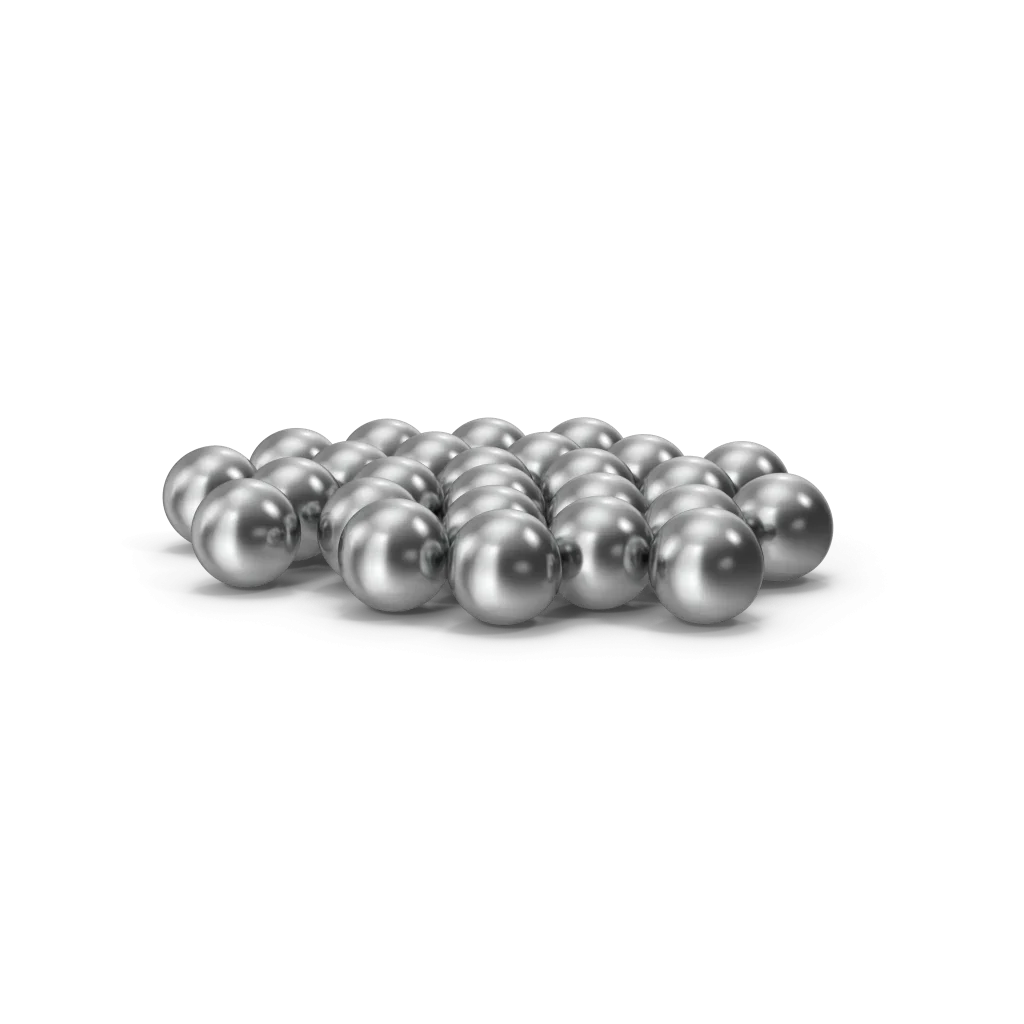

Absolutely. We offer a full welding system including ceramic ferrules, aluminum balls, welding machines, and accessories.

Every production step is strictly inspected — from raw material selection to final shipment — to guarantee consistent quality and welding performance.

Feel free to contact us with any questions or to request a quote. Our team will respond within 24 hours.

Hear what our global partners say about our service and reliability.

© 2019-2025 All Rights Reserved | zocstudweld