ZOC Stud Weld is a leading manufacturer of weld studs, shear studs, and stud welding machines. We provide high-quality stud welding solutions for global industries.

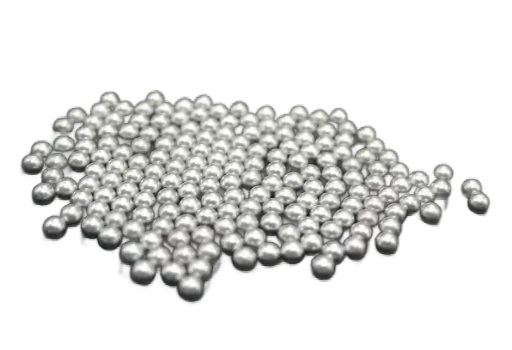

Alum flux balls are essential auxiliary materials used in stud welding, particularly for aluminum stud applications. These small spheres contain a specialized flux compound that helps remove oxides and impurities during the welding process, ensuring clean, strong, and reliable welds. When placed inside the ceramic ferrule or directly under the aluminum stud, the flux ball melts under high temperature, creating the right environment for bonding. At ZOC Stud Weld, we offer high-purity alum flux balls in consistent sizes, designed to match various stud welding specifications. With stable composition, good reactivity, and reliable performance, our flux balls help improve weld quality and efficiency across mass production lines. Ideal for use in industries like shipbuilding, automotive, and steel structure fabrication.

Enhances the fusion between aluminum studs and base material by removing surface oxides during welding.

Quickly melts under heat, promoting efficient cleaning action and reducing welding time.

Made from refined materials to ensure consistent flux performance and minimal contamination.

Reduces porosity and weak points, resulting in cleaner, stronger, and more reliable weld connections.

Uniform sphere sizes ensure stable placement, melting behavior, and compatibility with welding equipment.

Compact, lightweight design allows easy storage, transport, and welding setup loading.

Alum flux balls play a vital role in the aluminum stud welding process. During welding, they are placed beneath or inside the ceramic ferrule along with the aluminum stud. When the arc is triggered, the intense heat causes the flux ball to melt rapidly. As it melts, the flux reacts with surface oxides on both the stud and the base metal, effectively cleaning them and enabling a strong metallurgical bond. This chemical reaction prevents contamination and reduces the risk of porosity or weak welds. The result is a clean, solid, and high-strength weld joint. At ZOC Stud Weld, our alum flux balls are engineered for consistent melting behavior, optimal reactivity, and compatibility with various stud sizes and welding conditions.

Alum flux balls are used specifically in the aluminum stud welding process to ensure clean, strong, and reliable welds. They serve as a fluxing agent that helps remove aluminum oxide layers formed on the surface of the stud and base metal. Without this step, proper bonding cannot occur, as aluminum oxide prevents effective fusion. When the welding arc starts, the flux ball melts and chemically cleans the metal surfaces, promoting a solid metallurgical connection. These balls are commonly used in industries such as automotive, shipbuilding, steel construction, and electrical enclosures, where aluminum studs are applied. ZOC Stud Weld offers high-performance alum flux balls tailored for precision and consistent welding quality.

High-purity flux powders are chosen to ensure clean welding results.

Materials are blended for uniform composition and consistent chemical performance.

Mixed powder is shaped into balls using a precision mold under high pressure.

Formed balls are dried to remove moisture and maintain structural integrity.

Balls are sintered at controlled temperatures to harden and stabilize the structure.

Finished balls are sorted by size to ensure uniform diameter and compatibility.

Each batch is checked for purity, shape, and reactivity to ensure quality standards.

Alum flux balls are manufactured through a precision process involving raw material blending, molding, and sintering. Each step is designed to ensure purity, uniform size, and optimal reactivity for aluminum stud welding applications.

Each batch is screened to ensure consistent diameter and weight for stable welding results.

Balls are inspected for cracks, dust, or irregularities that may affect weld quality.

Flux composition is analyzed to guarantee high purity and reliable chemical reactivity.

Flux balls are applied in actual welding to evaluate bonding performance and arc behavior.

Samples are tested to confirm fast and even melting performance during arc initiation.

Products are tested under various conditions to ensure long-term storage without degradation.

We are committed to customer satisfaction by delivering high-quality stud welding solutions. At ZOC Stud Weld, we ensure every weld stud, ceramic ferrule, and stud welding machine meets your industrial needs with precision and reliability.

We are a trusted manufacturer committed to delivering high-performance stud welding products tailored to your industrial needs.

With over 30 years of manufacturing experience, ZOC Stud Weld understands the requirements of global factories, wholesalers, and OEM clients. Our team ensures reliable supply, stable quality, and professional service in every shipment.

Need assurance? We welcome all your questions and are ready to support your projects with confidence.

✔ ZOC Stud Weld is ISO-certified, with strict quality control at every stage.

✔ We supply only premium weld studs, ceramic ferrules, and stud welding machines.

✔ Our products are manufactured using fully automated production lines for consistency.

✔ We support OEM & customized packaging based on your brand requirements.

✔ Competitive prices without compromising on quality.

✔ Fast response, on-time delivery, and flexible support for long-term cooperation.

Want to explore how we can work together? Let’s connect today.

At ZOC Stud Weld, we ensure every shipment of alum flux balls is packed securely and delivered efficiently. Depending on your order size, we offer multiple packaging options such as sealed plastic bags, reinforced cartons, or moisture-proof drums to protect the flux balls during transit. Each package is clearly labeled for easy identification and traceability. For bulk orders, we use wooden cases or pallets to enhance loading safety and prevent damage during international shipping. With strong partnerships in global logistics, we guarantee fast delivery to your warehouse, factory, or distribution center—on time, every time. From packaging to shipping, we take every step seriously to maintain product integrity and support your production schedule.

Our Standard Packaging Methods:

Lightweight and cost-effective for general packaging.

Ideal for bulk loading and forklift handling.

Strong and secure for heavy or high-value goods.

Durable and protective for long-distance shipping.

Our Standard Shipping Methods:

Efficient for large cargo at a lower shipping cost.

Fast delivery for urgent and time-sensitive orders.

Stable delivery across long inland distances.

Flexible for short routes and door-to-door service.

ZOC Stud Weld has been providing high-quality stud welding solutions for over 10 years. We understand the key concerns buyers face before making a purchase. Here are the most common questions our customers ask before finalizing a deal.

An alum flux ball is a small, round welding aid used in aluminum stud welding. It contains flux compounds that clean surface oxides during the welding process to ensure a strong bond.

Aluminum surfaces naturally form oxide layers that prevent proper fusion. The flux in alum flux balls reacts with these oxides, allowing clean, solid welds.

Place the alum flux ball under or with the aluminum stud before welding. It melts under arc heat, activating its cleaning function during the weld.

ZOC Stud Weld offers alum flux balls in various standard diameters to fit different stud sizes and welding equipment requirements.

Yes. Our alum flux balls are packed in moisture-proof, impact-resistant packaging for long-term storage and safe global shipping.

Absolutely. We support OEM services and can produce flux balls based on your specific technical or packaging needs.

Feel free to contact us with any questions or to request a quote. Our team will respond within 24 hours.

Hear what our global partners say about our service and reliability.

© 2019-2025 All Rights Reserved | zocstudweld