ZOC Stud Weld is a leading manufacturer of weld studs, shear studs, and stud welding machines. We provide high-quality stud welding solutions for global industries.

ZOC Stud Weld is a trusted manufacturer of stud welding products in China since 1993. We specialize in weld studs, shear studs, ceramic ferrules, and stud welding machines—designed for heavy-duty industrial use and OEM customization. Contact us for high-quality supply and competitive factory prices.

Please feel free to contact us at any time for a quotation or further details.

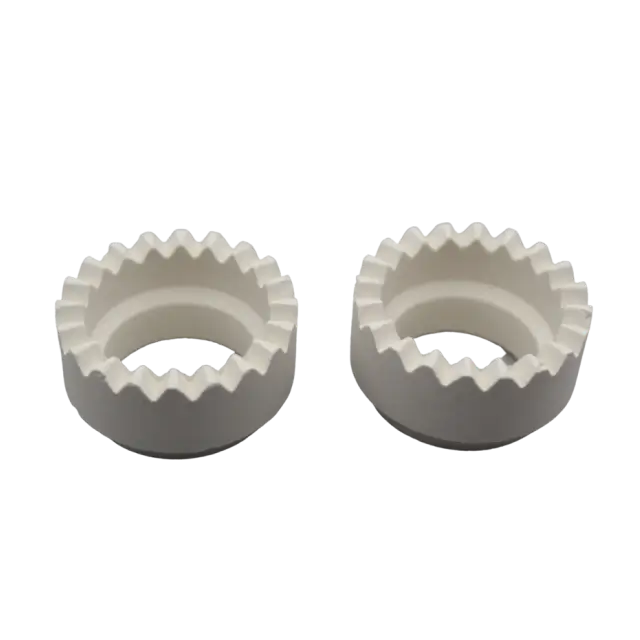

Ceramic ferrules are essential components in stud welding, serving as heat-resistant insulators that ensure precise arc control and strong welds. Commonly used with shear connectors and steel structures, these ferrules protect the weld pool from oxidation and retain heat for better fusion between the stud and base metal. At ZOC Stud Weld, we manufacture ceramic ferrules using high-purity clay and advanced kilning processes, ensuring consistent dimensions, high thermal shock resistance, and minimal breakage during shipping. Our ferrules are compatible with various welding standards and specifications worldwide. Whether for bridge construction, high-rise buildings, or industrial fabrication, our ferrules deliver stable quality, competitive pricing, and global OEM support.

Withstands extreme welding temperatures without cracking or deforming.

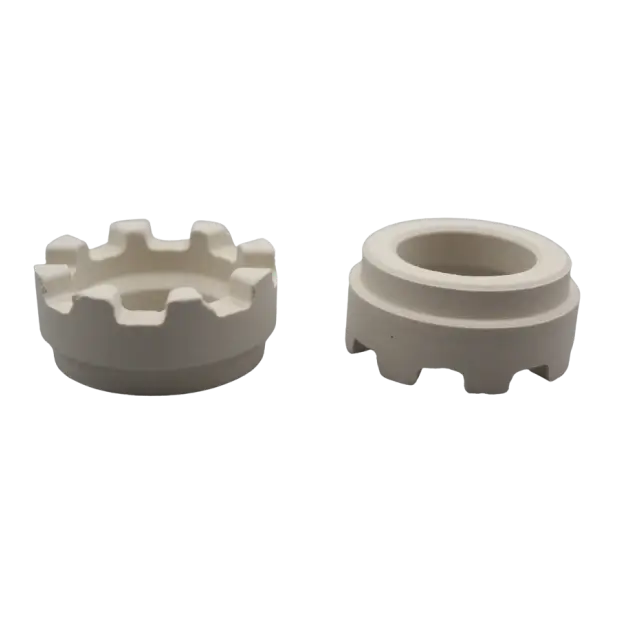

Uniform size and shape ensure perfect fit with studs and welding equipment.

Provides a stable arc environment, improving welding accuracy and reducing defects.

Strong ceramic material reduces breakage during shipping, storage, and installation.

Blocks air during welding to prevent oxidation, resulting in cleaner and stronger welds.

Compatible with international welding standards and various stud welding systems.

Ceramic ferrules play a key role in the stud welding process by acting as heat-resistant barriers around the weld area. When a stud is welded to a steel surface, the ceramic ferrule is placed around the stud to contain and shape the molten metal. It helps concentrate the heat, maintain arc stability, and protect the molten weld pool from air, preventing oxidation. The ferrule also prevents metal spatter and helps form a clean, uniform weld fillet. Once the weld is complete and cooled, the ferrule is usually broken away, leaving behind a strong, reliable weld connection. Their function is simple but essential for safe and effective stud welding.

Ceramic ferrules are mainly used in stud welding applications, especially in steel structure construction. Their primary purpose is to assist in the arc welding process by enclosing the weld zone, controlling heat concentration, and shielding the molten metal from air exposure. This ensures a clean, solid bond between the weld stud and the steel base. Ceramic ferrules are widely applied in bridge building, shipyards, power plants, and high-rise construction where shear connectors or weld studs are needed. They help achieve strong structural joints, reduce welding defects, and improve overall safety and performance of welded connections in large-scale industrial projects.

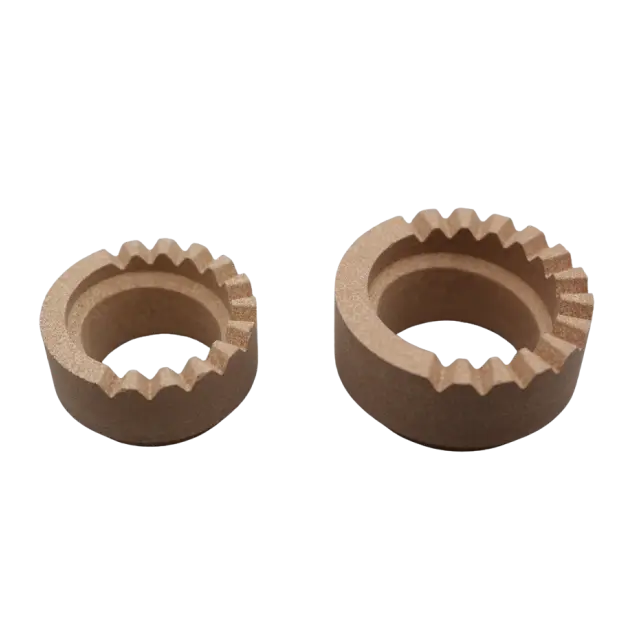

High-purity clay and minerals ensure excellent heat resistance and durability.

Clay and additives are blended uniformly for optimal molding consistency.

Ferrules are shaped using precision molds to maintain dimensional accuracy.

Formed ferrules are air-dried to remove moisture and prevent cracks.

Ferrules are fired at high temperatures to achieve hardness and heat resistance.

Each batch is checked for cracks, deformities, and size tolerance.

Ferrules are sorted, counted, and securely packed to avoid damage in transit.

Ferrules can be tailored in size, shape, and packaging based on customer requirements.

Ceramic ferrules are produced through precise processes to ensure durability, heat resistance, and consistent quality. From raw material selection to high-temperature firing, each step is carefully controlled to meet welding performance standards.

Each ferrule is precisely measured for inner/outer diameter and height to ensure consistent welding fit.

Fired at over 1300°C to achieve high density, low porosity, and excellent thermal shock resistance.

Tested at high welding temperatures to confirm resistance to cracking, melting, or thermal deformation.

All ferrules are checked for visible defects like cracks, chips, or burrs that may affect welding quality.

Drop and compression tests ensure ferrules remain intact and undamaged during transport and storage.

Formed with precise molds to ensure consistent size, smooth edges, and accurate fit.

We are committed to customer satisfaction by delivering high-quality stud welding solutions. At ZOC Stud Weld, we ensure every weld stud, ceramic ferrule, and stud welding machine meets your industrial needs with precision and reliability.

We are a trusted manufacturer committed to delivering high-performance stud welding products tailored to your industrial needs.

With over 30 years of manufacturing experience, ZOC Stud Weld understands the requirements of global factories, wholesalers, and OEM clients. Our team ensures reliable supply, stable quality, and professional service in every shipment.

Need assurance? We welcome all your questions and are ready to support your projects with confidence.

✔ ZOC Stud Weld is ISO-certified, with strict quality control at every stage.

✔ We supply only premium weld studs, ceramic ferrules, and stud welding machines.

✔ Our products are manufactured using fully automated production lines for consistency.

✔ We support OEM & customized packaging based on your brand requirements.

✔ Competitive prices without compromising on quality.

✔ Fast response, on-time delivery, and flexible support for long-term cooperation.

Want to explore how we can work together? Let’s connect today.

At ZOC Stud Weld, we understand that ceramic ferrules are fragile and demand extra care during transportation. That’s why we use strong, industry-grade packaging methods to ensure each piece arrives intact and ready for use. Our ferrules are first sorted, then packed in protective cartons or wooden cases with shock-absorbing materials to minimize breakage. For bulk shipments, pallets are used to secure stability during handling. Every box is clearly labeled for easy identification and safe stacking. Whether shipped by air, sea, or land, we track every shipment and provide timely updates. Our goal is to deliver your ceramic ferrules fast, safe, and damage-free—no matter where you are in the world.

Our Standard Packaging Methods:

Lightweight and cost-effective for general packaging.

Ideal for bulk loading and forklift handling.

Strong and secure for heavy or high-value goods.

Durable and protective for long-distance shipping.

Our Standard Shipping Methods:

Efficient for large cargo at a lower shipping cost.

Fast delivery for urgent and time-sensitive orders.

Stable delivery across long inland distances.

Flexible for short routes and door-to-door service.

ZOC Stud Weld has been providing high-quality stud welding solutions for over 10 years. We understand the key concerns buyers face before making a purchase. Here are the most common questions our customers ask before finalizing a deal.

Ceramic ferrules are used in stud welding to control the arc, protect the weld zone, and shape the molten metal during welding. They ensure clean, strong welds.

No, ceramic ferrules are typically single-use. They are broken or damaged after the welding process and should be replaced for each weld.

Yes. Made from high-temperature resistant ceramics, they can withstand extreme welding heat without cracking or deforming.

Ceramic ferrules come in a wide range of standard sizes to match different stud diameters. Custom sizes are also available upon request.

They are packed in strong cartons or wooden boxes with foam or separators to prevent breakage during transport and handling.

Most ceramic ferrules are compatible with standard stud welding machines. We also offer OEM options tailored to your equipment.

Feel free to contact us with any questions or to request a quote. Our team will respond within 24 hours.

Hear what our global partners say about our service and reliability.

© 2019-2025 All Rights Reserved | zocstudweld